UV printers have revolutionized the printing industry with their advanced technology and versatile applications. This article delves into the world of uv flatbed printer, exploring their working mechanism, benefits, applications, and future prospects.

What is a UV Printer?

UV printers, or ultraviolet printers, utilize ultraviolet light to cure or dry the ink as it is printed. Unlike traditional printing methods that use solvent or water-based inks, UV printers use special inks that are instantly cured by UV light, resulting in vibrant and durable prints.

How Do UV Printers Work?

The core of UV printing technology lies in the use of UV-curable inks and UV light-emitting diodes (LEDs). Here’s a step-by-step breakdown of the process:

- Ink Application: UV printers apply ink to the printing surface just like conventional printers.

- UV Curing: Immediately after the ink is deposit, UV LEDs emit ultraviolet light, which cures the ink almost instantaneously.

- Drying: The UV light causes a photochemical reaction that solidifies the ink, eliminating the need for drying time.

This rapid curing process allows for high-speed printing on various materials, including paper, plastic, glass, metal, and even wood.

Benefits of UV Printers

UV printers offer several advantages over traditional printing methods, making them a popular choice for businesses and individuals alike:

- High Quality and Durability: The immediate curing process ensures that prints are smudge-proof and resistant to scratching. UV prints are also resistant to fading, making them ideal for outdoor use.

- Versatility: UV printers can print on a wide range of substrates, expanding the possibilities for creative and commercial applications.

- Eco-Friendly: UV printing produces fewer volatile organic compounds (VOCs) compared to solvent-based inks, making it a more environmentally friendly option.

- Efficiency: The rapid curing process reduces production times, increasing efficiency and throughput.

- Cost-Effective: Although the initial investment in uv flatbed printer technology may be higher, the long-term savings in drying time, labor, and ink costs can be substantial.

Applications of UV Printers

The versatility and efficiency of UV printers have led to their adoption in various industries:

- Advertising and Signage: UV printers are widely use to produce high-quality banners, posters, and signs that withstand outdoor conditions.

- Packaging: The ability to print on diverse materials makes UV printers ideal for packaging solutions, including custom labels and boxes.

- Textiles: UV printing on fabrics allows for intricate designs and vibrant colors, catering to the fashion and home decor industries.

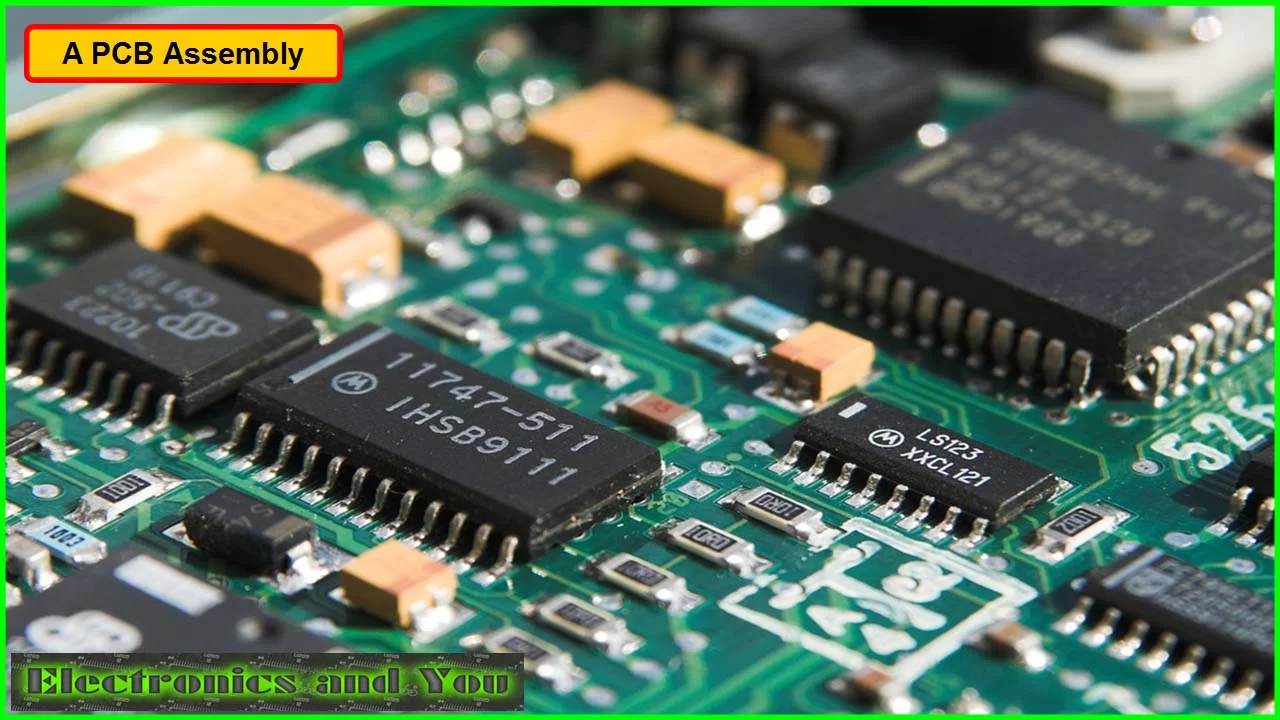

- Electronics: UV printers can print directly on electronic components, providing durable and precise markings.

- Interior Design: Customize wallpapers, tiles, and furniture panels can be produce with UV printing, offering unique design solutions.

Future of UV Printing

The future of UV printing looks promising, with continuous advancements in technology and expanding applications. Innovations such as 3D UV printing and improvements in ink formulations are expect to drive the industry forward. Additionally, the growing emphasis on sustainability is likely to further promote the adoption of eco-friendly UV printing solutions.

Conclusion

UV printers represent a significant leap in printing technology, offering high-quality, durable, and versatile printing solutions. As technology continues to evolve, uv flatbed printer is poise to become even more integral to various industries, providing endless possibilities for creative and commercial applications. Whether for advertising, packaging, textiles, electronics, or interior design, UV printers are set to shape the future of printing.